There is more to the demolition than just knocking things down. Contractors have to have eyes in the back of their heads and have their eyes peeled for many potentially dangerous elements.

Demolition is a carefully regulated, thoroughly researched business. Demolition contractors must be meticulous about both the safety of employees and environmental safety, or else risk losing their business licenses. As with regular contractors, demolition experts have legal requirements to follow strict standards for employee safety. They must also comply with standards for deconstruction techniques that ensure a secure environment. Hazardous construction materials, like asbestos, should always be safely extracted before demolition can take place. For Birmingham Demolition, visit a site like https://www.hammerjack.co.uk/

Some forward-thinking demolition companies have even exceeded government standards by finding new and innovative ways to reuse old building materials, instead of sending them directly to the landfill. Because they have a unique perspective on how best to demolish buildings, commercial demolition experts can teach you a lot about selecting housing materials, building methods and more. Focusing on environmentally friendly dismantling has a definite cost-saving value for residential builders, plus there has been a surge in consumer demand for green construction.

Limiting exposure to hazardous chemicals

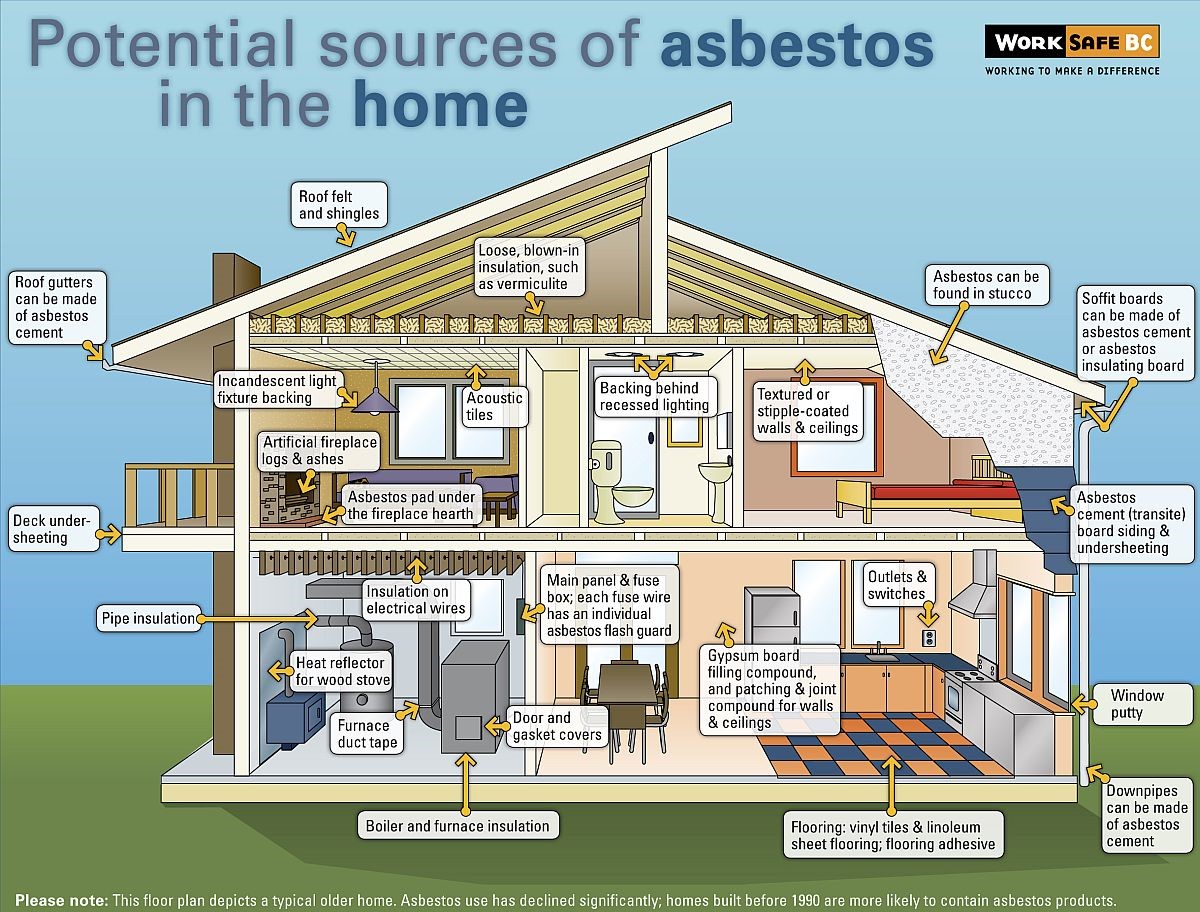

It goes without saying that residential building contractors are aware of the hazards of asbestos, lead and other toxic substances in the construction of houses. Newer properties do not contain toxic materials, but it is not unusual for a contractor to be hired to retrofit or bring an old house up to code.

Wood dust containing formaldehyde

It is possible for wood dust to get lodged in the nose when breathed in and is estimated to have led to cancer of the nose in some woodworkers. The wood panel particles sometimes contain toxic formaldehyde; when wood is cut or manipulated, formaldehyde-laced dust is sent into the air, posing a great risk to workers nearby. For this reason, contractors recommend wearing protective respiratory equipment when dealing with particles and panels.

Synthetic mineral fibres

These are a fibrous product made of ceramic, fibreglass and rock wool. Studies have found these fibres are not as dangerous as asbestos, so they are still used in sound and thermal protection products. They can cause irritation of the eyes, nose and throat but there remains some question as to whether SMFS can also cause lung cancer, because sometimes they contain fibreglass. Industrial demolition experts recommend workers wear respirators and protective clothing when SMF contact is possible.

Lead paint

One danger that is often overlooked is the danger of burning steel beams that have been painted with lead paint. Just a small number of painted beams can leave a worker exposed to lead levels in the air that are off the charts. Workers must be provided with respirators, protective clothing and hand washing stations.

These are just some of the demolition materials that contractors must carefully monitor and prepare for when taking down buildings. There are, in fact, a whole set of standards for disassembly procedures.